Being ahead of new trends and offering a diverse product range is essential for all ice cream producers.

Testing with small batches to understand feasibility and study how the market accepts new products can be a real advantage. Having the right equipment to do this means you won’t need to interfere with production of your main products, translating in big savings of costs, time and resources.

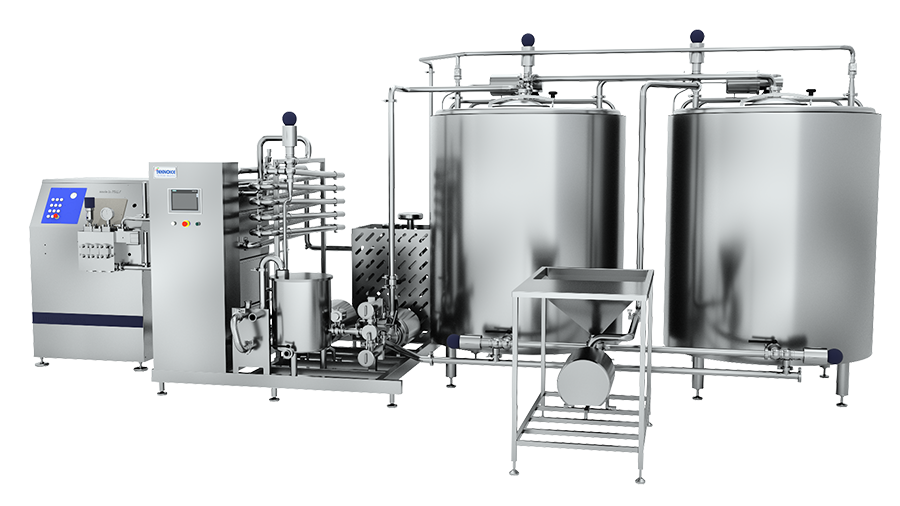

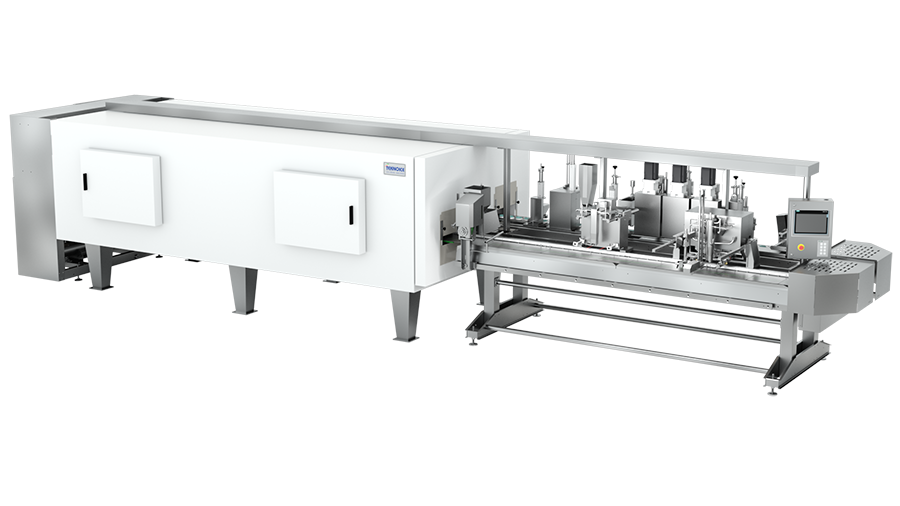

Teknoice offers a complete range of equipment built especially for the purpose of R&D. This equipment can be used to test small batches of a new recipe or to test a new product in small volumes. Our mini production lines meet all our usual standards, allowing you to produce the same quality of ice cream you can expect on larger lines.