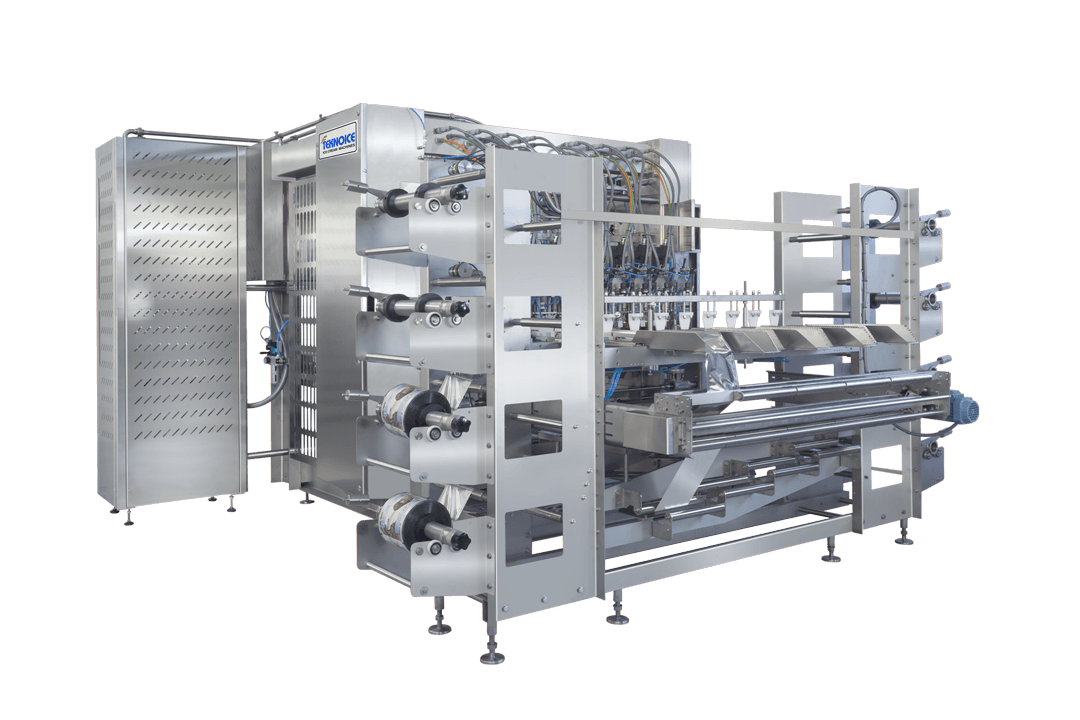

Teknowrap multilane automatic wrapping machines: high productivity for small spaces.

Available in many sizes, ranging between 4 and 2 lanes, Multilane wrapping machines can be suite to any productivity need. They can be added to any extrusion line or at the end of any molded stick line with up to 24 lanes. Sticked products as well as bars and sandwiches can be wrapped with these machines. Ball cones and wafer cups can also be wrapped on our lines once they have been through the hardening tunnel.

Teknowrap Multilane

- Reel carrier on each lane

- Stainless steel main body

- Longitudinal towing-sealing rollers with brushless motors, transversal sealing and cutting jaws

Flowpack multilane machines: combining experience and R&D

The Teknoice team is focused on making every machine as efficient as possible, seamlessly transitioning from one operation to the next. Safety and waste reduction is the main focus of our latest updates.

Every Teknowrap multilane includes a solution introduced by Teknoice: every sealing group and transversal cutting device is heated by oil, with a double electric heating system. This system is used to avoid heating resistors on sealing parts. Using oil means less stops of the machine, resulting in less maintenance and repairs are needed. Teknoice’s solution allows all cutting jaws to be equally heated.

Teknoice has also recently added an automated system for discharging defective products: a huge advantage that avoids boxing them or to having empty bags.

From production equipment to wrapping: pick-up and lay-down

All multilane automatic wrapping machines receive products directly on the wrapping film, which is then sealed around the ice cream, just as in reversed flow packs.

Teknoice’s solutions can be grouped in two main categories and the choice depends on the equipment ahead of the line (which can be pre-existing) and on the ice cream itself. Both with pick-up and lay-down systems, products will be collected from the trays or the pincers and gently placed on the Teknowrap multilane.

The first solution is ideal for sandwiches, ball cones, wafer cups and bars. The second is better for sticked products, both extruded and molded.

The lay-down system is a specialty for Teknoice as its smooth movements allow for a flawless production with high precision.

Modelli proposti

| # rows | Capacity strokes/min | Hourly production (pieces/hour) |

|---|---|---|

| 4 | 50 max per row | 11.500/12.000 |

| 6 | 50 max per row | 17.000/18.000 |

| 8 | 50 max per row | 23.000/24.000 |

| 10 | 50 max per row | 29.000/30.000 |

| 12 | 50 max per row | 35.000/36.000 |

Contact us to find out more, or to choose the most suitable model for you:

This model can be included in your production line, or as a module in our complete range for a whole production line.