Subscribe to our newsletter

Keep updated with our latest innovations.

Sky’s the limit when it comes to Industrial Ice Cream Creations using Automated Fillers

- 15/06/2023

- Posted by: Debora Bolis

- Category: BLOG

If you plan to produce ice cream at the industrial level, you must include a filling machine in your fleet of ice cream-making machines. This is critical for several reasons. First, it is all about efficiency and volume production. The accurate dispensing of ice cream into the various containers of choice, from cups to cones and everything in between, is as important as the automation of the process, which allows meeting volume demand while ensuring consistent portion sizes and minimizing waste.

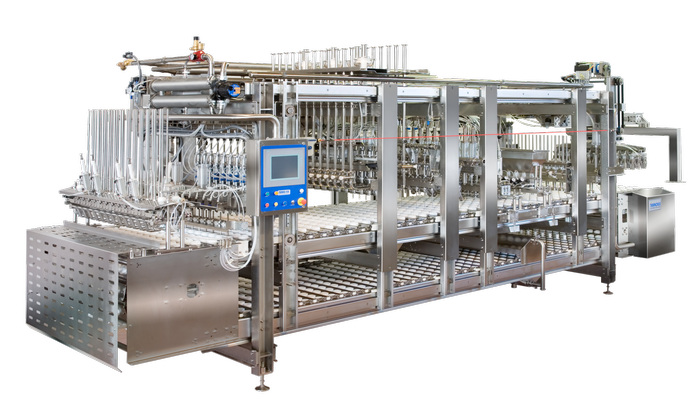

Even more importantly, an automated ice cream filler allows you to produce a wide range of ice cream products, from single-flavor cups to elaborate creations with multiple flavors and toppings, making your ice creams truly stand out from the crowd. And speaking of standing out, Teknoice does indeed distinguish itself as a manufacturer of high-quality filling machines. Teknoice filling equipment offers maximum customization of shapes and sizes and the accurate positioning, dosing, and spraying processes required to create unique products every time.

How does a filling machine work, and what is it, exactly?

An ice cream filling machine is a specialized piece of equipment used in the production of ice cream. There are different models of filling machines, such as rotary or linear, which are selected based on the type of ice cream to produce and the complexity of the product desired. Factors considered include the number of toppings or flavors, the appearance, and the preferred style and size of the container.

The primary function of an automated filling system is to accurately fill ice cream into containers, including cups or cones, quickly and efficiently. A filling system enhances efficiency and ensures consistent product quality by automating the process of accurately filling ice cream into containers. It streamlines production and plays a crucial role in meeting consumer demands for delicious frozen treats.

Cones, cups, tubs, and more: all the ice creams suitable for an automated filling system

Once you have an automated filler available for your ice cream production line, you have a multitude of options at your disposal. Firstly, you can fill all sorts of containers and sizes. Equally important, you can unleash your creativity regarding the ice creams you can make. They can range from traditional single-flavor ice creams with a singular base flavor, such as vanilla, chocolate, strawberry, or mint, to more sophisticated mixed-flavor ice cream. The ice cream filling units can also produce ice creams with multiple flavors blended together, such as swirls or ribbons of different flavors within a single container.

Furthermore, fruit-based ice creams are also possible, as the automated filler can handle the filling of ice creams made with fruit purees or fruit concentrates and even those with added nuts,crushed cookies, chocolate chips, marshmallows, or candies, allowing for many customized ice cream creations.

Customization rules with Teknoice Automated Filling Systems

Teknoice is renowed for its high-quality ice cream production machines and automatic filling systems. One of its strengths is its ability to offer flexible equipment to meet every need. Teknoice’s filling machines are designed to fill cups, cones, tubs, and more. They are equipped with 1 to 6 filling rows depending on the dimensions. The machines have a mechanical capacity ranging from 20 to 50 strokes per minute and 2,400 to 18,000 pcs/h.

Special nozzles can be used based on the specific product requirements. A feature that generates great interest is the adjustable rotary movement of the machines, allowing the creation of special effects. Additionally, the topping station is capable of dispensing liquid chocolate, dried nuts, or cocoa powder. Furthermore, the closing/packaging station can be customized to meet specific requirements, ensuring the best options are at your fingertips when choosing the perfect equipment for your production needs.

Teknoice: Your Ideal Automated Fillers

Stainless steel frame, touch screen operation panel, dosing systems installed on a guide rail, easy setup, quick-release system for changing ice cream shapes, volumetric chocolate dosing system, heating for chocolate dosing stations, individual and adjustable solid ingredients feeding system: all these are key features of the Teknoice filling machines, which are available in both linear and rotary models depending on your requirements.

With numerous customization options and the flexibility provided by these machines, the best way to select your ideal filling system is to contact Tecknoice for a consultation. They will provide all the necessary information to help you choose the best machine for your ice cream-making endeavor ensuring that your product stands out from the crowd! Contact Tecknoice today!