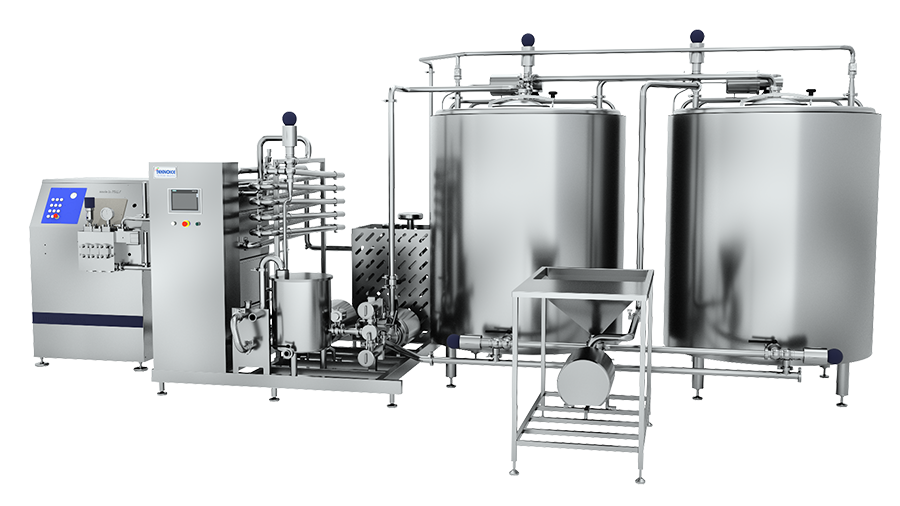

HTST system for ice cream production

The Teknomix HTST (High Temperature Short Time) is a solution for industrial ice cream mix preparation in large quantities: perfect for medium and large producers with a productivity range between 1200l/h and 5000l/h.

The system is composed of different stations which all cooperate to mix ingredients and create a final product which is well homogenized and pasteurized, with the finest possible texture. The quality of ice cream is determined by not only the ingredients but how well this process is completed.

The Teknomix HTST method heats the mix up to 85°C in two steps: first in heating tanks and then by the heat exchanger. The temperature must be preserved for at least 40 seconds. A probe will check that the temperature remains at 85°C. Should it detect a different temperature, the process will be repeated by sending the mix back. This allows all of the mix to complete the process successfully.

An advantage of Teknoice’s HTST pasteurization system is the heat exchanging which occurs between the ice cream mix and mains or tower water. In many parts of the circuit the two liquids will meet, allowing the temperature to increase or decrease. This results in a saving of costs, energy and space.