Made with only Italian and European materials and parts, Teknoice equipment is 100% produced in Italy, closely followed by our R&D team to ensure that quality is maintained at every stage.

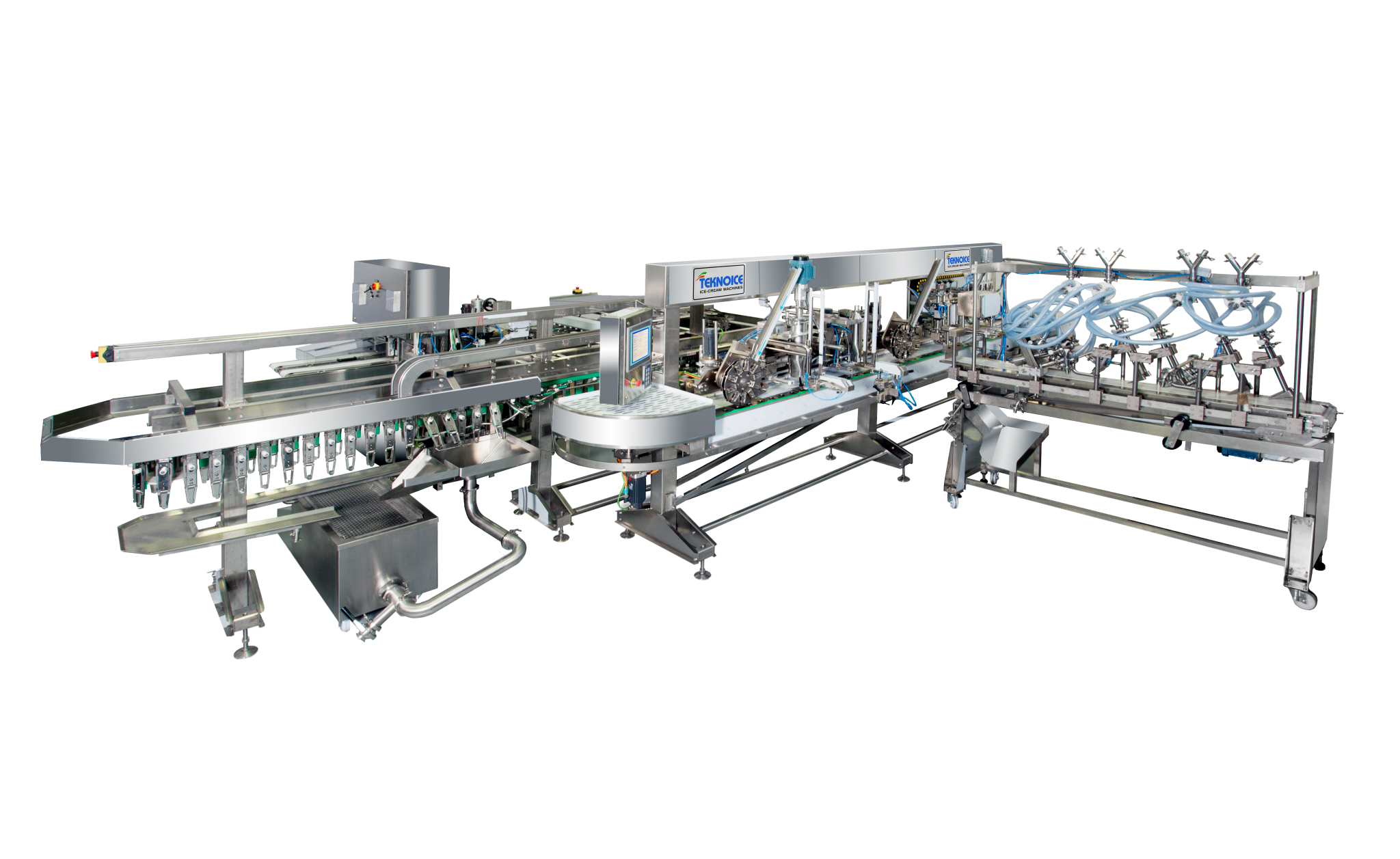

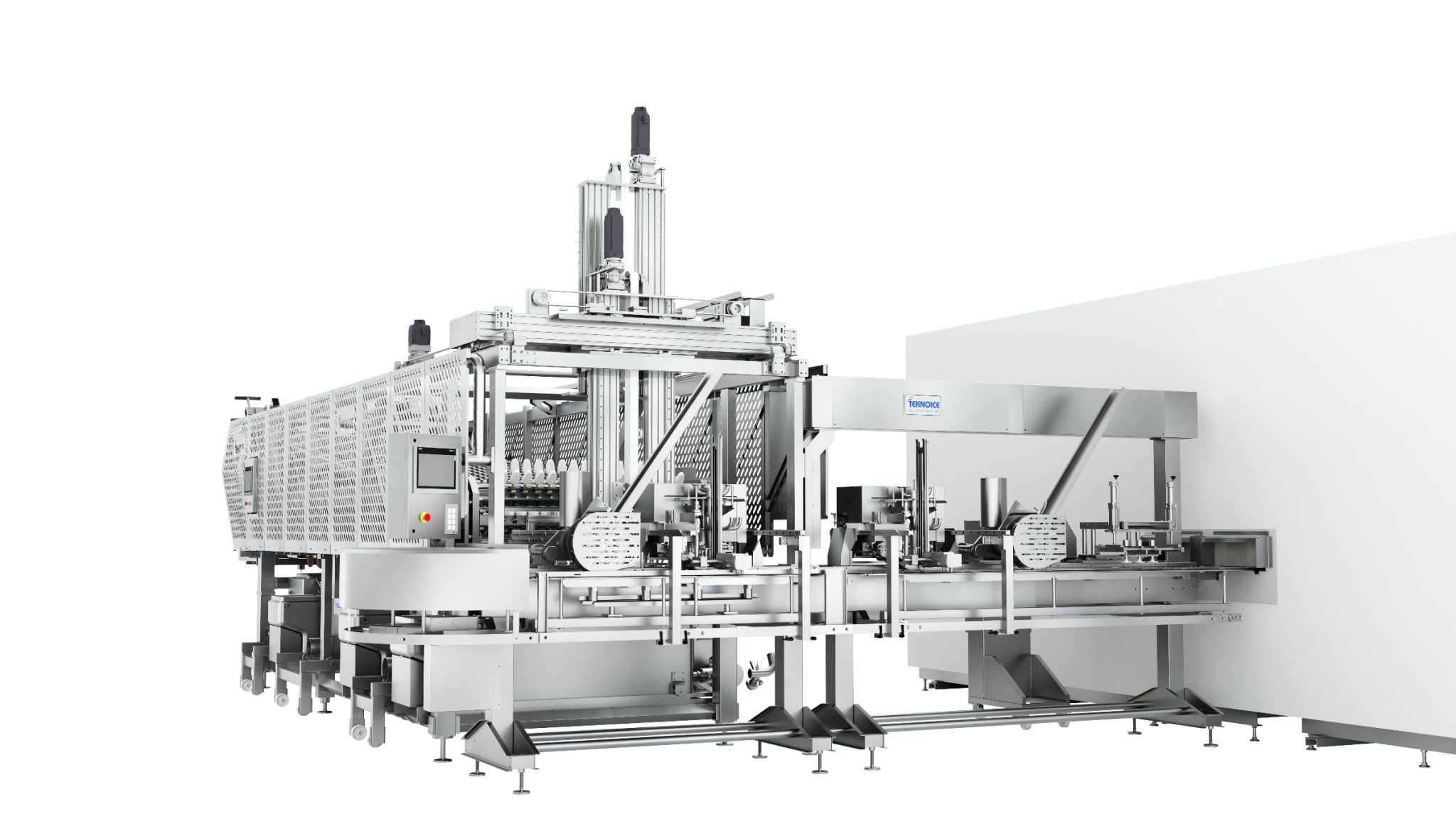

The following are standard on all Teknoline Ice Cream extrusion lines:

- Stainless steel main frame

- Touch screen operation panel

- Working table with extruding or dosing station

- One set of trays

- Pincers pick up

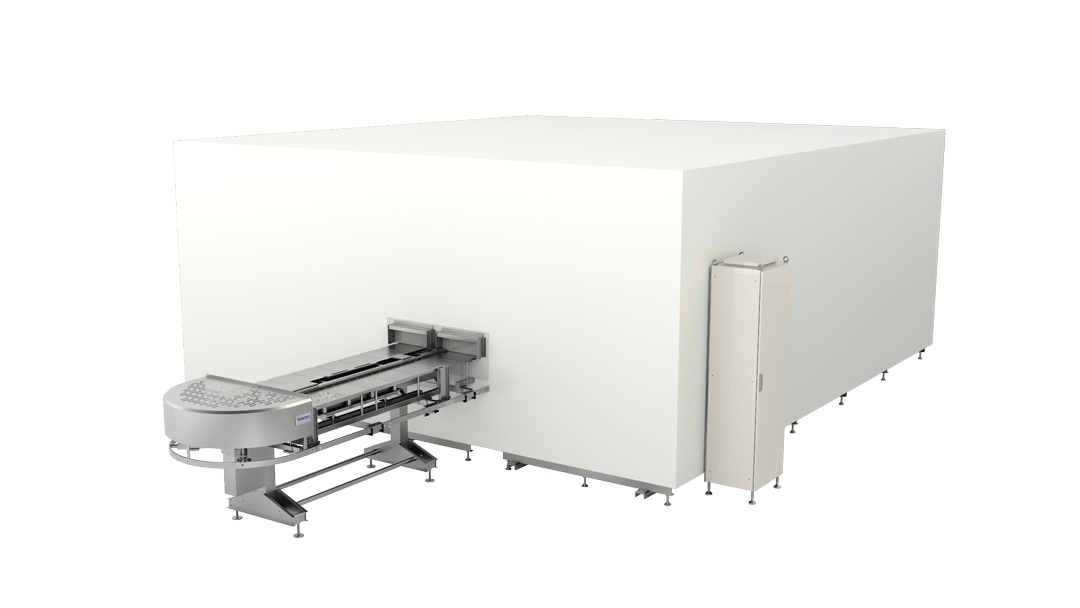

- Isothermal box

- Refrigerating unit (FREON or CO2)

- Evaporators (for FREON, Ammonia and CO2)

All extrusion lines are designed to work as a modular system that allows us to install different station and accessories.

Below is a list of our most common solutions. For each we will evaluate the project at hand and determine everything that is needed to produce the desired frozen treat or ice cream product.

Extruder: essential for all stick ice creams, bars, sandwiches, bites, individual desserts and much more. The shape is defined by the customer’s need and determines how the ice cream is positioned on the trays.

Cutting system: can be single or double, with hot wire or blades.

Chocolate/Syrup tank: positioned after the hardening tunnel, the ice cream gets coated and after drying it can be wrapped.

Cookie wheel: Teknoice has designed a system that places cookies or wafers on the trays of the working table, ice cream will be extruded and covered by a second cookie or wafer by a second wheel.

Enrober: typically used in the production of bars, bites or individual desserts. The ice cream, after being cooled in the hardening tunnel, can go through a special structure that will cover them with chocolate on all sides and push them towards the cooler.

Dosers: some products such as ball cones or wafer cups can be dosed directly onto the trays thanks to a special multiple dosing group that follows the trays and finally enters the hardening tunnel.

Nota: può aggiungere un’ultima riga di testo che includa la kw: ice cream extrusion line