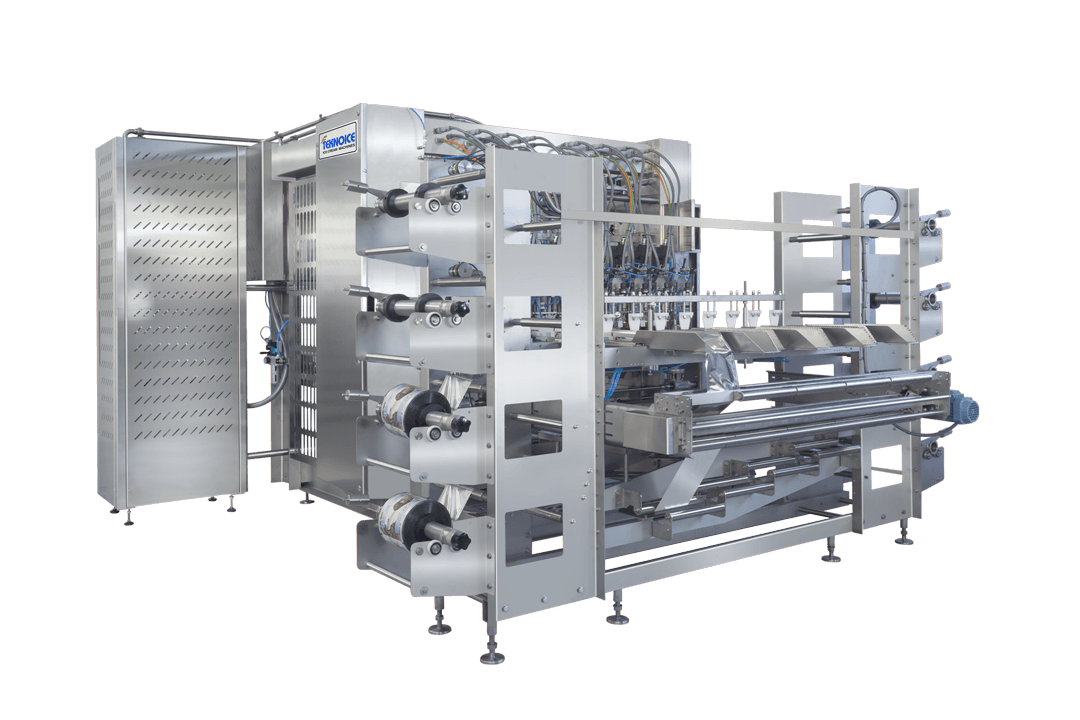

Every Teknoline ends with an automatic wrapping machine for industrial ice cream. Teknoice offers a complete range of flowpack, standard or reversed, mono or multilane wrapping machines.

All Teknoice wrapping machines are built with quality materials, parts and high precision. This is essential for minimizing waste and maintaining our quality protocols. Many years of experience goes into the production of every machine, incorporating technology that focuses on optimizing production and checking quality at every step.

Single, double or multilane

Choosing the right machine is achieved by studying the production line to understand which solution grants the best possible ROI. The right wrapping machine will consider both requested productivity and the characteristics of the ice cream. Teknoice’s team will find the right solution to optimize space constraints, budgets and production needs.

Standard or reversed flowpack?

Teknoice offers standard flowpack solutions and reversed – a solution that completely switches the way ice cream is wrapped inside the film. This system gently places the product directly from the extrusion line pincers onto the wrapping material. This solution can help to preserve the integrity and the hygiene of the product. This reversed method of wrapping is standard on all Teknowrap Multilane systems as it results in a more efficient production with less waste and errors.